Waterlox ORIGINAL Finishes are interior finishes that work as a finish for interior projects. Waterlox ORIGINAL Finishes are available in three gloss levels: gloss, semi-gloss and satin. Waterlox ORIGINAL enhances the color, richness, and grain of wood. It is a proprietary handmade Tung Oil and resin composition that yields a rich, hand-rubbed look that’s durable and easy to maintain.

What You’ll Need

Safety

- Chemical resistant gloves and eye protection (e.g.: safety glasses and/or goggles), hearing protection (if using buffing equipment).

- NIOSH/MSHA-approved respirator during application (for organic vapor).

- NIOSH-approved dust mask for sanding (if sanding to bare wood).

- Read and carefully follow label instructions, guidelines, warnings and cautions.

General

- Vacuum, broom and clean, lint-free rags.

- Paint thinner or mineral spirits.1

- Painter’s tape.

- Box fan(s) to insure cross-ventilation and adequate dry.

Product Options

Waterlox Sealer Product Options

ONE of the WATERLOX sealers as listed below is REQUIRED to seal the wood prior to the application of Waterlox ORIGINAL Finish as the first coat of the system.

- ORIGINAL Waterlox ORIGINAL Sealer & Semi-Gloss Finish – TB 5284

Required first coat of the system. This Tung Oil-based sealer seals the wood from within. It also beautifies, richens and shows off the depth of the wood. One to two coats (depending upon the hardness of the wood) are required for adequate film build.

- TRUETONE® Color-Infused Tung Oil – TB 70XX

Required first coat of the system. This innovative high-solids, VOC compliant, color-infused Tung Oil-based sealer and stain seals the wood which minimizes grain raise. It also beautifies, richens and shows off the depth of the wood. Must be driven into the wood and excess removed.

- UNIVERSAL Tung Oil Sealer (UTOS) – TB 1000

Required first coat of the system. This innovative high-solids, VOC compliant, Tung Oil-based universal sealer seals the wood which minimizes grain raise. It also beautifies, richens and shows off the depth of the wood. Must be driven into the wood and excess removed. One coat is required for adequate film build.

Waterlox ORIGINAL Finish Product Options

Use 2 coats of the finish. It is a proprietary resin-modified Tung Oil finish that forms an elastic, water resistant film to protect interior wood surfaces.

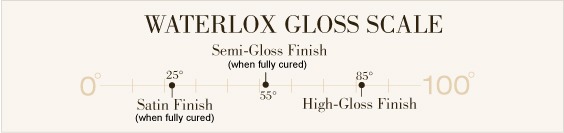

- Waterlox ORIGINAL Gloss Finish – TB 6044

Results in an 80-85° gloss finish.

- Waterlox ORIGINAL Sealer & Semi-Gloss Finish Semi-Gloss – TB 5284

Results in a 50-55° gloss finish.

- Waterlox ORIGINAL Satin – TB 6044

Results in a 20-30° gloss finish.

Coverage

- One gallon covers approximately 500 square feet per coat

- One quart covers approximately 125 square feet per coat

- One 2 fl oz bottle covers approximately 6 square feet per coat

Tools

Not recommended for use with a roller.

For Large Projects:

- An 8-12″ lambswool applicator and a paint pan large enough for chosen applicator.

- A quality natural bristle brush or paint pad recommended for use with oil-based finishes for cutting in edges.

- Abrasive pads for sanding and smoothing between coats (if necessary):

- Maroon pads or surface preparation pads (SPP pads) are recommended.

- Also 320-grit sandpaper, 0000 steel wool or other equivalent abrasive.

For Small Projects:

- A quality natural bristle brush, lambswool hand pad or paint pad recommended for use with oil-based finishes.

- Abrasive pads for sanding and smoothing between coats (if necessary):

- 320-grit sandpaper, 0000 steel wool or other equivalent abrasive.

Testing

Waterlox ORIGINAL finishes will alter the appearance of the wood. Proper testing of the entire process should be completed before beginning.

Preparation

- Vacuum the surface thoroughly with and across the grain to remove as much sanding dust as possible, including all surfaces that could hold dust.

- Lightly dampen a rag with mineral spirits or paint thinner and wipe the wood surface to pick up any remaining sanding dust. Allow the mineral spirits to evaporate (15-30 minutes) before applying.1

- Tape off or cover any surfaces not being coated.

Product Handling

- Waterlox ORIGINAL Gloss and Waterlox ORIGINAL Sealer & Semi-Gloss Finish – NO shaking or stirring required or advised.

- Waterlox ORIGINAL Satin Finish – Shake or stir contents before use. Stir contents occasionally during use.

- BATCHING. If more than one container of finish is needed to complete a coat, the containers should be batched together before starting the coat.

Application Steps

- Apply Waterlox ORIGINAL Sealer & Semi-Gloss Finish, UTOS, MARINE Sealer or TRUETONE® Color-Infused Tung Oil following proper application and drying directions. Apply two (2) coats of Waterlox ORIGINAL Finish at the chosen gloss level with 24 hours between coats.

- Pour out the amount of product needed for the first coat.

- If working from a previously opened container, straining through a medium to fine mesh paint strainer may be required.

- Apply first coat of Waterlox ORIGINAL Finish with the grain and at the recommended spread rate.

- Allow to dry for 24 hours.

- Sanding between coats is not required for adhesion but may be done for aesthetics. Lightly sand the surface with a synthetic abrasive pad (medium/maroon recommended).

- If sanding, lightly dampen a mop, lint-free rag or micro-fiber mop with water or regular mineral spirits1 (paint thinner) to remove dust. Allow to evaporate 30-45 minutes (until dry appearance) before applying Waterlox ORIGINAL Finish.

- Apply the second coat of Waterlox ORIGINAL Finish.

Application Procedure

Large Projects:

- Clean the new, unused applicator with painter’s tape, lint roller, in the dryer or with a vacuum before starting.

- Pour out the Waterlox ORIGINAL Finish product into a paint tray.

- Dip the applicator fully into the paint tray.

- Following the grain, pull the applicator toward the opposite wall evenly. Hold the applicator at a slight angle to maintain a wet edge.

- When cutting in edges do not work more than 5-10 feet from the field-applied finish.

Small Projects:

- Clean the new, unused lambswool applicator or pad with painter’s tape, lint roller, in the dryer or with a vacuum before starting.

- Pour out the amount of finish needed for the job or dip applicator into the can and spread evenly.

- Following the grain, lightly drag the applicator or brush from one end of the project to the other to remove applicator marks. Hold the applicator or brush with light pressure and maintain a wet edge.

- Wipe off any drips with a clean rag if necessary.

Clean Up and Disposal

Clean application tools immediately with regular mineral spirits1 or paint thinner. Do not pour extra product down the drain! Allow rags that are wet with product to dry in a well-ventilated area before disposal. Properly dispose of rags, applicators and waste. DANGER! Rags, steel wool or waste soaked with Waterlox may spontaneously catch fire if improperly discarded. Immediately after use, place rags, steel wool or waste in a sealed water-filled metal container. Read carefully other cautions on the product label.

Storage

- Visit waterlox.com/storage. Keep container closed when not in use. Read carefully other cautions on the product label.

Drying and Ventilation

- Waterlox ORIGINAL Finishes will dry through exposure to oxygen (oxidation).

- Dry time before recoating is 24 hours.

- Poor ventilation, high humidity or cool temperatures may increase dry times.

- Read carefully other directions and cautions on the product label.

- For full ventilation details, visit Drying, Ventilation, Curing and Circulation.

Cleaning and Care

Visit the cleaning and care guide for more information.

Re-Coat and Maintenance

Visit the re-coat and maintenance guide for more information.

This guide is intended to be a standard application procedure. See the ORIGINAL product page for additional guides and tips.

DANGER! COMBUSTIBLE LIQUID AND VAPOR CONTAINS MINERAL SPIRITS. VAPOR HARMFUL. MAY AFFECT THE BRAIN OR NERVOUS SYSTEM CAUSING DIZZINESS, HEADACHE OR NAUSEA. CAUSES EYE, SKIN, NOSE AND THROAT IRRITATION. NOTICE: Reports have associated repeated and prolonged occupational overexposure to solvents with permanent brain and nervous system damage. Intentional misuse by deliberately concentrating and inhaling the contents may be harmful or fatal. Keep away from heat and flame. Prevent build-up of vapors by opening all windows and doors to achieve cross-ventilation. Use only with adequate ventilation. Do not breathe vapors or spray mist. Ensure fresh air entry during application and drying. If you experience eye watering, headache or dizziness or if air monitoring demonstrates vapor/mist levels are above applicable limits, wear an appropriate, properly fitted respirator (NIOSH/MSHA approved) during and after application. Follow respirator manufacturer’s directions for respirator use. Close container after each use. Avoid contact with eyes, skin and clothing. Wash thoroughly after handling. FIRST AID: In case of eye contact, flush immediately with plenty of water for at least 15 minutes and get medical attention; for skin, wash thoroughly with soap and water. If you experience difficulty in breathing, leave the area to obtain fresh air. If continued difficulty is experienced, get medical assistance immediately. If swallowed, do not induce vomiting. Call physician immediately. If spilled, contain spilled material and remove with inert absorbent. Dispose of contaminated absorbent, container and unused contents in accordance with local, state and federal regulations.

WARNING! Cancer and Reproductive Harm – www.P65Warnings.ca.gov

WARNING: If you scrape, sand or remove old paint, you may release lead dust. Lead is toxic. Exposure to lead dust can cause serious illness, such as brain damage, especially in children. Pregnant women should also avoid exposure. Wear a NIOSH-approved respirator to control lead exposure. Clean up carefully with a HEPA vacuum and a wet mop. Before you start, find out how to protect yourself and your family by contacting the National Lead Information Hotline at 1-800-424-LEAD or log onto www.epa.gov/lead.

KEEP OUT OF REACH OF CHILDREN

1 If regular mineral spirits or paint thinner is not available in your area, there are alternatives. Visit waterlox.com/mineralspirits.